The earthing or grounding system is the heart of any electrical installation. The safety of the people and equipment connected to it depends on its design, its execution and its condition, as the excess current will flow to earth, preventing personal injury and failure of the electrical components connected to it.

The function of the earthing system in an electrical installation is to dissipate in the ground the current intensities of any nature that may originate, whether from fault currents, at an industrial frequency or due to atmospheric discharges.

For proper operation, fulfilling any of the above functions, the earthing system must have a low resistance so that there is no excessive voltage increase.

Earthing: what are its usefulness and importance?

Earthing has two main functions: to ensure the safety of people and the electrical appliances connected to it. Earthing provides a path for electrical current to flow safely to the ground in the event of a system fault or overload, reducing the risk of fire, electrocution and damage to equipment.

In addition, effective earthing ensures that the voltage in the system is stable and remains within safe limits. This is especially important in systems with sensitive equipment that voltage fluctuations can easily damage.

Grounding is also crucial for the proper operation of protective devices such as circuit breakers, fuses and surge protection devices. Without a reliable grounding system, these devices cannot function properly and the system can be damaged.

Grounding: design and implementation

To make a proper earthing or grounding system, it is first necessary to know the terrain on which it is to be installed to make the connections between its elements in the most efficient way.

1. Measuring the soil resistivity

The resistivity of the soil is known through a geoelectric survey. The measurement of soil resistivity makes it possible to determine the layout, depth, number and type of elements needed according to safety and functional requirements.

The soil resistivity determines the project parameters of the grounding system such as the optimal burial depth; the appropriate materials according to the corrosion rate in the soil; the number, type and appropriate arrangement of electrodes required. This way, the desired resistance value and the highest safety of the system are obtained.

Aplicaciones Tecnológicas S.A. has an ADVANCED GEOELECTRICAL STUDIES service to optimise grounding system projects thanks to the expert characterisation of the ground.

2. Materials for an earthing system

The materials used in an earthing system will vary slightly according to the resistivity of the ground.

Earth electrodes

General earthing is usually done employing a ring or mesh of bare, buried horizontal conductors, supplemented by vertical electrodes to reduce resistance.

Earth pits

Earth pits usually stand towards the outside of buildings. Their function is to provide an accessible manhole for any tests and inspections.

The connection to the earth pit stands at the bottom of an excavation, through a device that allows the disconnection of the earth conductors and must carry an earth symbol.

Earth bonds: permanent and mechanical

To make the connections necessary to implement an earthing or grounding system, it is advisable to use a welding method that ensures that these connections can last for the entire service life of the installation.

APLIWELD® Secure+ exothermic (also called aluminothermic) welding is the result of a process that achieves the molecular bonding of two or more metallic conductors employing a chemical reaction. This molecular bonding improves the mechanical, electrical and corrosion properties over any mechanical bonding.

In addition, the tablet format and remote electronic initiator kit, achieve much more efficient results, saving costs and providing extra safety.

Conductivity enhancers

Conductivity enhancers are used in soils with high resistivity, where achieving a low earth resistance value may be impossible even with multiple electrodes, to retain soil moisture and provide ions that significantly reduce resistance in a long-lasting and corrosion-free manner.

How is the performance of an earthing system optimised?

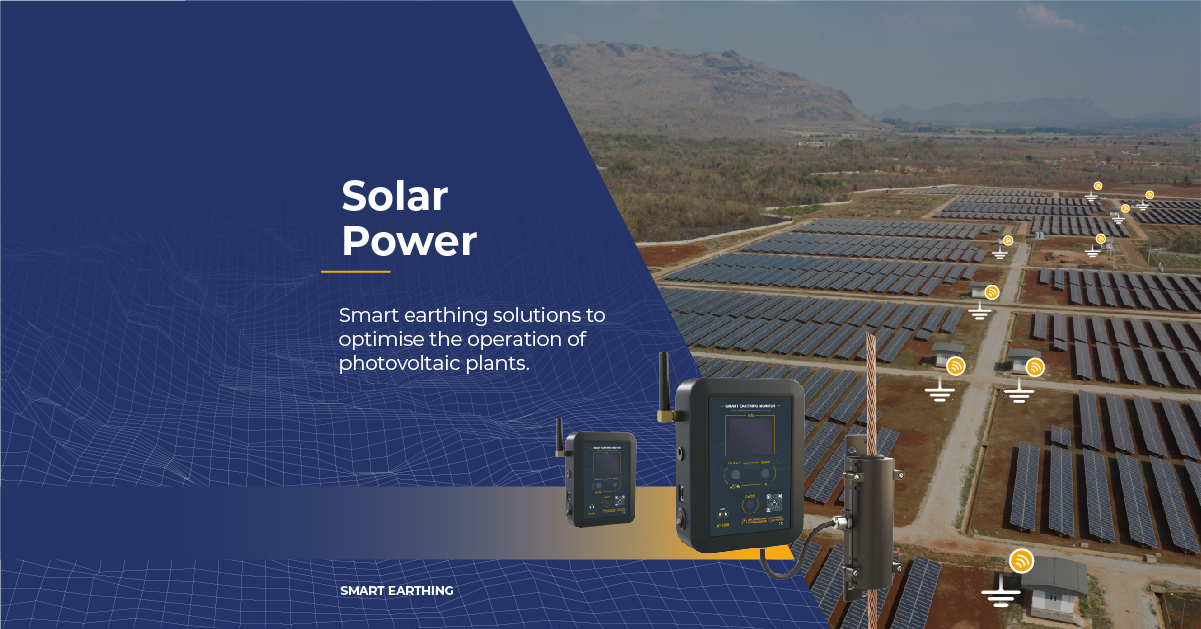

Earthing or grounding is an essential safety element that requires regular maintenance. In order to control the condition of the earthing system and to be aware of its condition and possible faults at all times, it is possible to continuously monitor the condition.

The monitorised earthing system makes it possible to observe the electrical dynamics attributable to malfunctions of the installation, but also of the equipment connected to the earthing system. In the event of any degradation or malfunction, this equipment generates an activity that can be used as an indicator. Thus, the earthing system becomes a sensor that identifies the progressive or sudden degradation of the connected elements.

Earthing systems 4.0

To guarantee the efficiency, safety and reliability of an earthing system, Aplicaciones Tecnológicas has an advanced service of earthing systems 4.0 that includes all the phases of the project, from its design to its execution and continuous monitoring.

You can contact us at this link if you want to know more about earthing systems.

If you wish, you can also attend any of our free online grounding training courses through our webinar page.