Apliweld® Secure+: Exothermic welding made efficient

The earthing systems and their connections should last for the lifetime of a building. Exothermic welding APLIWELD® Secure+ technology meets this objective better than other weldings or traditional practices such as mechanical connections.

- Aplicaciones Tecnológicas

- /

- Smart Earthing

- /

- APLIWELD® Secure+ exothermic welding

Exothermic welding

made efficient

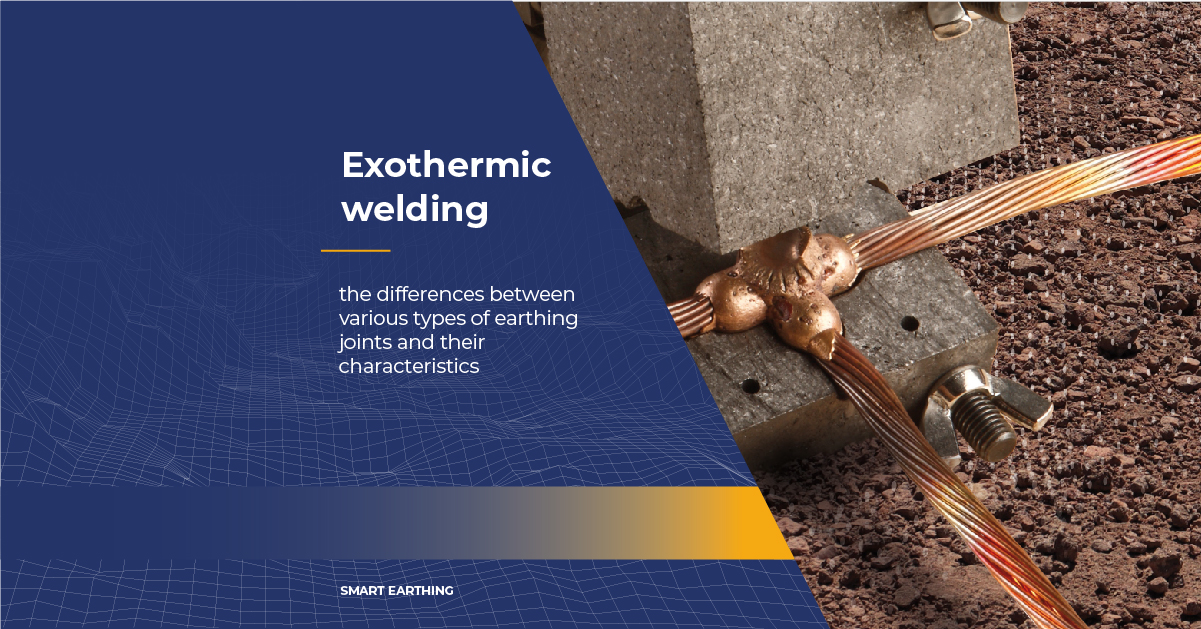

Exothermic welding Apliweld Secure+ is the result of a process that achieves the molecular union of two or more metallic conductors through a chemical reaction. This molecular bond improves the mechanical, electrical and corrosion-related properties with respect to any mechanical connection.

The innovative tablet format of exothermic welding Apliweld® Secure+ and the electronic ignition offers much more efficient results, saving costs and providing an extra in security.

Apliweld®

Secure+ advantages

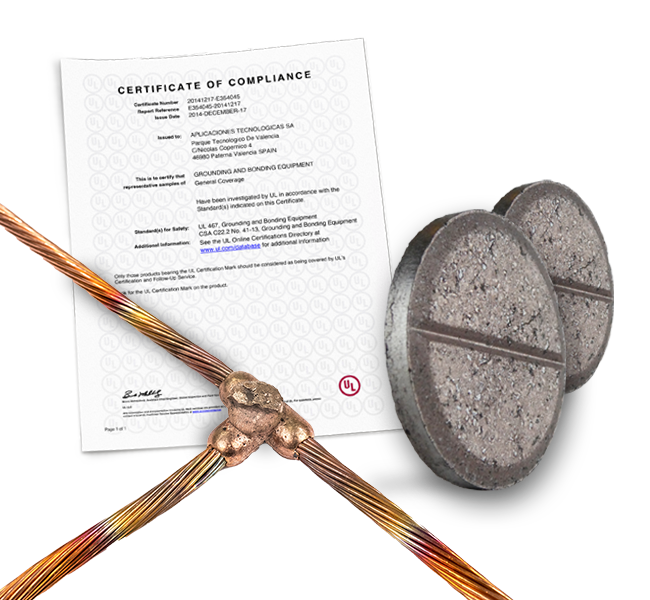

UNIONS

The exothermic welding Apliweld® Secure+ is the best mode to make permanent, reliable and high conductivity connections in every installation that requires earthing connection. The molecular union, not only mechanic, ensures the connection during the lifetime of the building in a well-defined process.

- Easy to use.

- Methodical procedure that avoids mistakes and malpractices.

- Certified connections.

SAVING

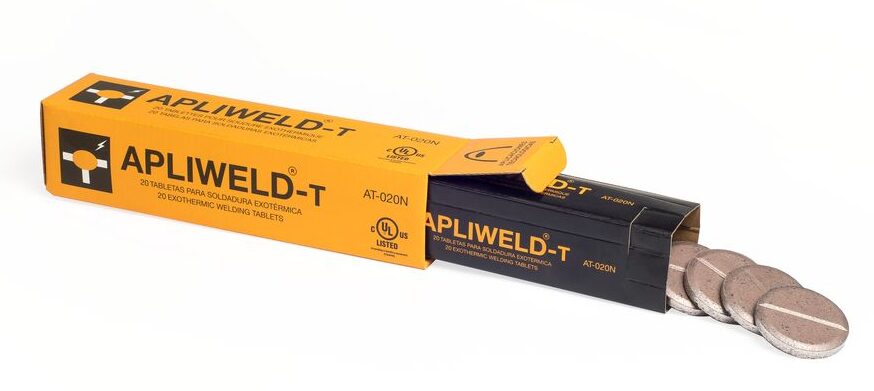

The unique tablet format of the Apliweld® Secure+ for any type of connection, it reduces logistics costs, minimizes errors and preparation times and increases the efficiency of the process, even in windy or humid weather conditions.

- Making all union types with one or several tablet, thus avoiding the need of multiple references.

- Optimize stock rotation and eliminate obsolete stocks.

- Does not absorb moisture, thus avoiding stock expiration.

- Starting rate higher than 99%, avoiding losses of material.

- Less mold wear due to less thermal shock.

- Reduces residual wastes when the labor is finished.

- Makes it easy to tackle unforeseen projects.

LABOUR SECURITY

Apliweld® Secure+ guarantees more security thanks to the wireless electronic ignition, now even via wireless control with Bluetooth activation and the use of non-flammable material for ignition. The electronic remote ignition is officially recommended by international labor entities.

- Avoids the risk of projections and burns.

- Avoids unactioned or inadequate ignitions.

- Avoids storage risks.

Why is Apliweld® Secure+ the most efficient exothermic welding system on the market?

Tablet format Compound

Unique compound reference for all welds

Contains no flammable material

Provides electronic ignition at a distance

Complies with:

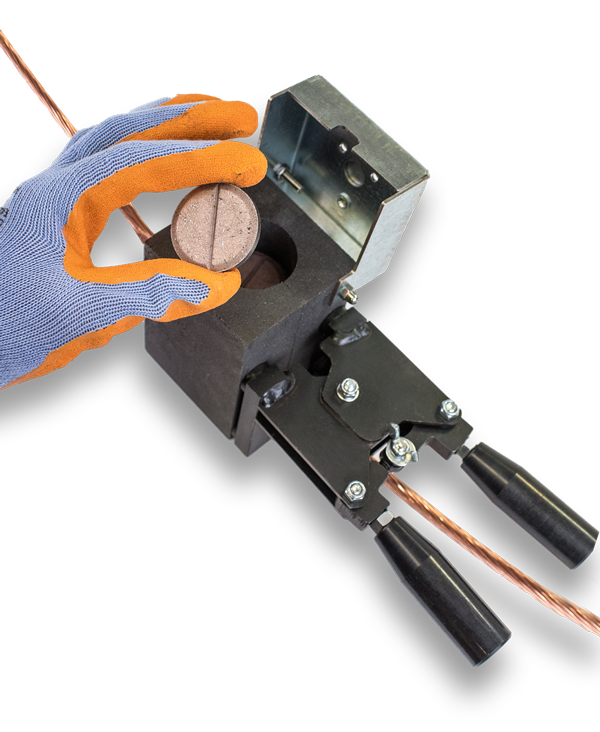

Apliweld® Secure+ system:

How it works?

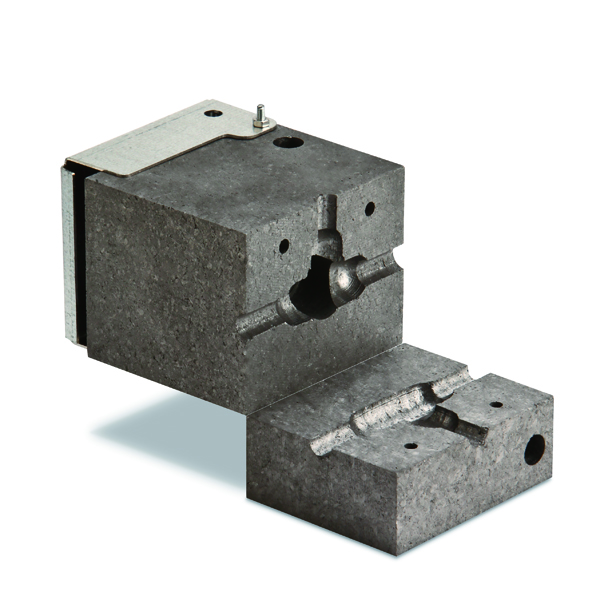

APLIWELD®-T: composed of universal welding in tablets.

APLIWELD®-E: electronic initiators.

APLIWELD KIT®-E: electronic ignition box.

Our Apliweld® products

Learn about Apliweld® Secure+ exothermic welding

Learn about specific mould

Learn about multiple mould

Related news

Contact