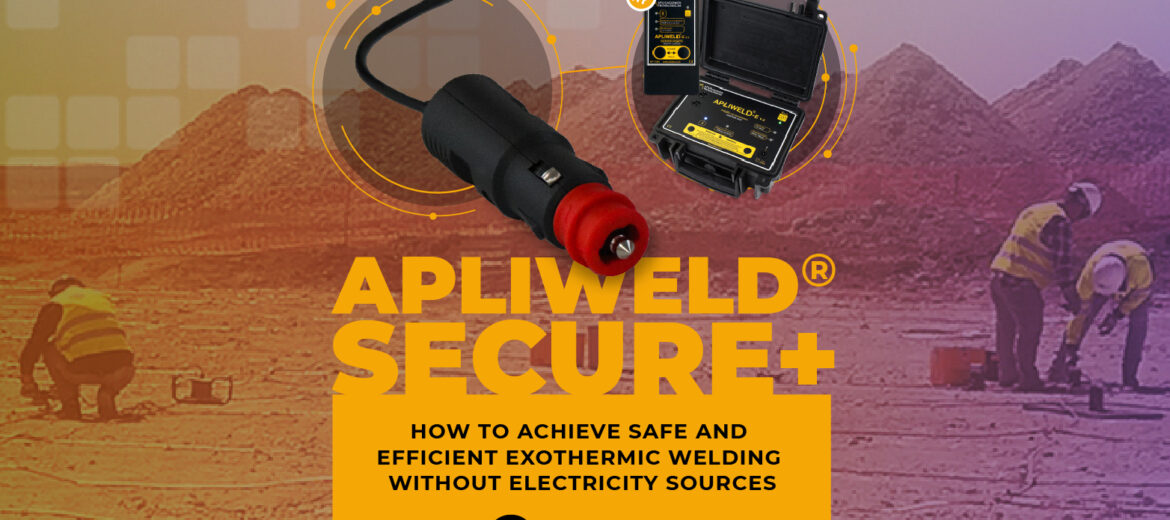

Earthing is a fundamental step in any electrical system installation. It is also essential for the proper functioning and safety of equipment and people, as it protects against potential differences that can be dangerous in both cases. The Apliweld® Secure + exothermic welding system allows permanent and reliable connections to be made safely thanks to its electronic initiator, but there is not always a source of electricity nearby. To overcome this obstacle, Aplicaciones Tecnológicas offers an add-on to charge the electronic initiator from any vehicle.

The realisation of a well-welded earthing system will make a difference to the durability of the installation. Exothermic welding, also known as aluminothermic welding, provides permanent, reliable and highly conductive joints.

The Apliweld® Secure+ system also makes these joints safer thanks to its electronic remote ignition system. The electronic ignition allows the user to stay away from sparks and possible material projections, eliminating the risks of operational errors.

The Technical Prevention Note (NTP) 1028 Safety in copper aluminothermic welding, from the National Institute for Safety and Health at Work, is dedicated to exothermic welding and recommends that ignition be carried out using electronic ignition, where the materials are not flammable and the user is kept away from sparks and material projections.

However, there are several external reasons that can delay the completion of this type of welding, a situation that can be avoided if auxiliary power supply systems such as the AT-121 N adapter.

Perform safe exothermic welding without impediments

One of the main obstacles an installer may encounter is the absence of power supplies in the vicinity. Generators and alternative sources of electricity are often available in construction environments, but are not always available or may not be operational at the time work begins on the installation of an earthing system.

For these cases, the Apliweld® Secure+ system from Aplicaciones Tecnológicas has an accessory that allows the battery of the electronic initiator to be charged by connection to the cigarette lighter of any vehicle.

The AT-121 N adapter fills a need in situations where there are no spare batteries, no batteries or other power source nearby but welding work cannot be postponed.

Within the range of accessories for the Apliweld® Secure+ system, the AT-121N adapter is designed to avoid delays in the absence of power sources by providing up to four hours of charging time for the electronic initiator without the need to postpone welding work.

Apliweld® Secure+: Efficiency and safety

The Apliweld® Secure+ system developed by Aplicaciones Tecnológicas focuses on the efficiency and durability of the joints and on the safety of the worker who makes them.

Exothermic welding allows connections to be made with better conductivity and greater efficiency than that achieved with mechanical joints, which are less resistant to the passage of time and prone to wear and tear due to corrosion.

Aluminothermic welding is used to achieve molecular bonding between copper, stainless steel, galvanised, bronze, and other conductors. The basis of the process is an exothermic chemical reaction in which the aluminium reduces the copper oxide producing the copper which fully or partially melts the conductors to be welded providing a connection superior to any mechanical joint, both with respect to mechanical and electrical properties.

The Apliweld® Secure+ system consists of a tablet charge, electronic initiator and remote ignition. Tablet fillers replace traditional powder fillers of different weights, simplifying the welding process by avoiding material loss due to powder spillage and facilitating storage.

More features: Apliweld® Selector

In the search for efficiency when installing earthing systems, Aplicaciones Tecnológicas has its own software for calculating exothermic welding earthing grid projects.

By entering a series of parameters (connections, conductors and quantity) it calculates how many moulds, tablets, ignition material and accessories are required for a given installation or project. The programme returns the references and quantities required, so that the final material to be acquired can be known.

Aplicaciones Tecnológicas also has a reference selector on its website to find out moulds, loads and accessories according to the type of joint.

If you want to know more about aluminothermic welding, you can contact us in this link.

You can also attend any of our webinars on exothermic welding at the following link.

References

- Tamborero del Pino, J. M., Polo Martí, E. & Fernández Manzzini, P. NTP-1028 Seguridad en soldadura aluminotérmica de cobre. (2014).