Lightning rods must be regularly inspected and maintained in accordance with national and international standards (UNE21186, NF-C 17 102, IEC EN 62305). These periodic inspections of the lightning rod allow detection of deviations from the reference standards or anomalies in the installation caused by environmental conditions (e.g. corrosion), incorrect handling (e.g. disconnection or theft), or other circumstances, such as extensions to the building where the lightning rod is located.

The inspection of the lightning protection system must be part of the maintenance routine of the buildings and the annual action plans.

Why is the maintenance of lightning rods necessary?

All lightning protection systems should have routine maintenance and monitoring carried out. If the lightning rod is not properly maintained, there is a risk that lightning strikes are not controlled nor their current conducted and dispersed safely.

The different elements of the lightning protection system can be deteriorated over time, reducing the safety levels of the system if they are not properly maintained.

For a lightning protection system to work optimally each and every part needs to be in good condition:

- The lightning rods, or air terminals must work correctly. In the case of the early streamer emission (ESE), the element that emits the upward leader should be fully operational to maintain the time of the advance of the ESE air terminal that has been measured in the laboratory.

- Down conductors must maintain continuity at all times and be well-fixed to avoid sparks and breakage.

- Ground resistance must remain below 10 ohms so the lightning current dissipates quickly, minimizing the return currents and the contact voltages, which that can be very dangerous for people.

How is the lightning rod revision carried out?

The procedure for lightning rod maintenance consists of two types of verifications:

Visual inspection in the maintenance of lightning protection systems

Check that:

- There is no damage due to lightning strikes.

- The lightning rod keeps all its elements in a good state.

- The continuity of the conductors is correct.

- The fixings are in good condition.

- There are no parts damaged by corrosion.

- The state of the equipotential bonding is correct.

Complete verification in the maintenance of the lightning protection system

The complete verification includes the visual inspections described above as well as other measures. It is necessary to verify the electrical continuity of the down conductors and the correct performance of the lightning rod according to the specifications indicated by the manufacturer.

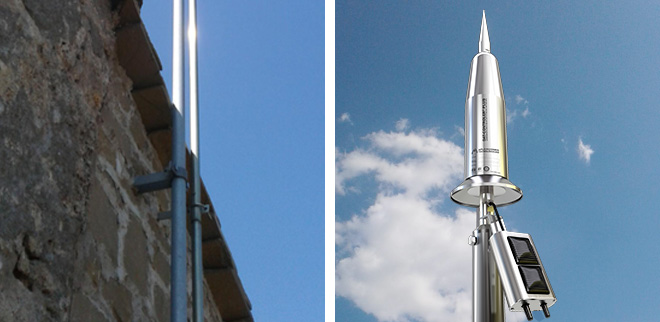

In the case of ESEs, the correct operation of the air terminals must also be checked. The lightning rods are installed at the highest point of the structure, always two meters above any element to be protected and usually on a six-meter mast. Therefore, in most cases, it is difficult to access these air terminals and puts the operator is put in danger when carrying out these inspections.

To make this maintenance task easier, Aplicaciones Tecnológicas has incorporated a remote tester into the ESE terminal DAT CONTROLER® REMOTE. By doing so, it is unnecessary to physically access the air terminal, since it has a system that daily checks its state and sends the result to a web application where the updated data can be consulted at any time.

Regarding the earthing system, it is essential to measure the earth’s resistance, as it could vary with time. It is also important to ensure that it remains below 10 Ω. It is recommended to check the earthing annually. In fact, in many countries, there is a regulation that requires this. If high earth values are recorded, it will be necessary to use a ground-enhancing product such as Conductiver Plus or adapt the system to include more earth rods.

Likewise, the inspection must verify that the electrical lines which require protection against overvoltages are protected with adequate surge protection devices.

After having carried out the inspections described and when deterioration or anomalies in the system are detected, it is essential to repair or carry out the necessary corrective measures in the shortest time possible to ensure optimum protection.

In both periodic inspections (visual and complete) the person in charge of the maintenance actions must elaborate a report which informs the inspections that have been carried out, providing data and photographs.

When should we inspect a lightning rod?

According to the standards, lightning protection systems must undergo an inspection whenever the structure of the building is modified or repaired and also when the structure has been struck by lightning. Therefore, it is very useful to have a lightning event counter that informs about the number of lightning strikes on the structure.

SMART LIGHTNING LOGGER is a smart system for real-time alert and recording of captured lightning strikes, which is installed in the down conductor of the lightning rod and, using IoT communication, reports the impact and its characteristics at the moment it occurs.

Even if these situations do not occur, the inspection of the lightning protection system should be made periodically. As part of the maintenance protocol, the following types of verifications are carried out:

- Visual verification: Annual revision for levels of protection I and II. For levels III and IV, the visual verification must be done at least every two years.

- Complete verification: For levels of protection I and II, the complete verification will be done at least every two years. For protection levels III and IV, the verification will be done at least every 4 years.

- Complete verification of the critical systems: This verification needs to be done at least once a year for all of the protection levels.

In some countries such as Mexico and India, among others, the rainy season has high rates of precipitation and is concentrated in a very short period of the year. In these cases, it is very important to carry out the maintenance of lightning rods before the beginning of this period of the year. Contact a specialist to perform necessary lightning protection system inspection and receive appropriate advice.

If you have any questions about lightning rod maintenance, please contact us by clicking here.

You can also attend any of our free online lightning protection training on our webinar page.