In Aplicaciones Tecnológicas we have two new videos of our Apliweld® Secure+ exothermic welding, both of them explain the usage of the specific and multiple graphite moulds. Before starting the videos, its convenient to know the concepts related with this type of welding.

What is exothermic welding?

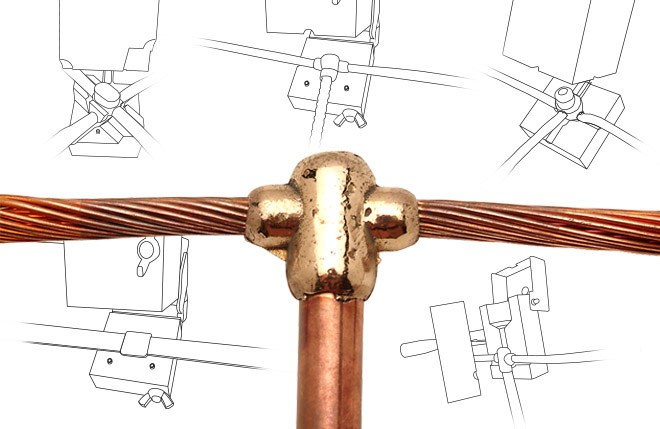

The exothermic welding, also known as aluminothermic or copper-aluminothermic welding, is a process that enables the union in a molecular level of the metallic conductors produced by a chemical reaction of aluminum oxide.

The result of the exothermic welding is a fusion, where the joint conductors convert into a unique inseparable piece. In this sense, the exothermic welding is better than a mechanical union, because it is a perfect conductor of current.

It’s a really efficient process, because its starting from a minimum contribution of voltage which the proper reaction creates energy, which is required in the welding process.

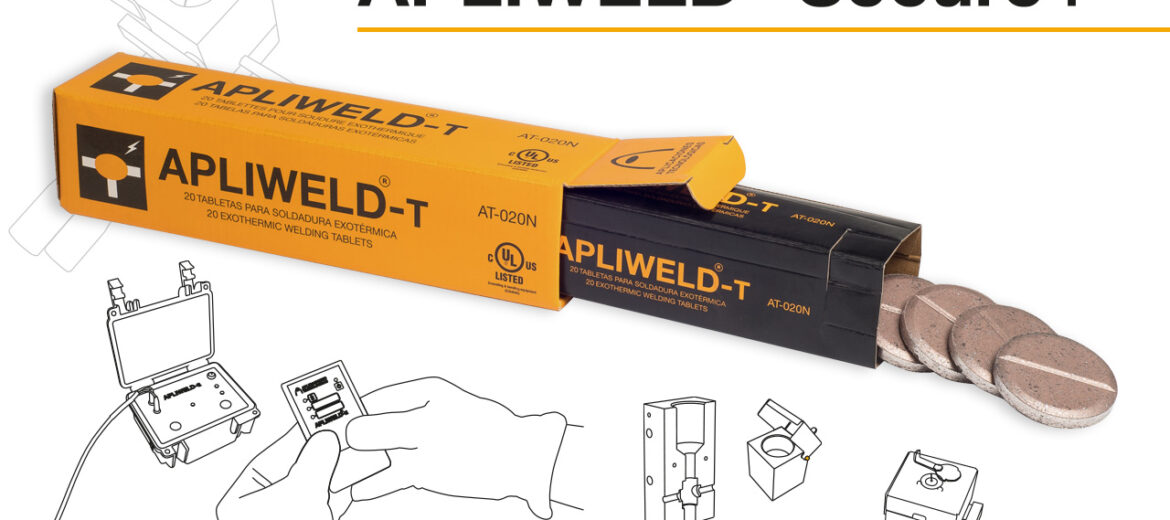

The process of exothermic welding stands out for the simplicity of itself, nevertheless, the charges of the different grammages, in dust, create some difficulties. Thanks to the innovation efforts of Aplicaciones Tecnológicas, the Apliweld® exothermic welding system in tablet format creates some advantages, because its usage it’s not affected by the wind, humidity or adverse meteorological conditions, it facilitates the storage and reduces the risk of accidents at work.

In which cases exothermic welding is recommended?

The exothermic welding is used to make every connection indicated by an earthing network, which implies copper conductor unions, although they can weld different metals too (cast iron, steel and cobrized steel) which require unions that maintain over time.

The result of that molecular union is perfect, because we maintain the same properties used in conductivity and mechanical resistance, which the proper conductor has.

Exothermic welding procedure

The process for making an exothermic connection is simple. Thanks to the electronic starter and ignition device Apliweld-E its even more secure, since the operator is far from the ignition, so therefore, the risk of any physical damage is zero. The Apliweld® welding procedure prevents work accidents.

Steps to make an Apliweld exothermic weld with electronic ignition

- Clean the conductors.

- Heat up the mold so it loses the humidity.

- Place the conductors and close up the mould.

- Place the correct tablet number.

- Place the electronical initiator and the ignition equipment.

- Initiate the process with the remote controller.

- Open the mold and see the result. Clean the spare aluminium oxide.

There are two types of graphite molds for exothermic welding: the specific and multiple moulds.

When should a specific or multiple mould be used in exothermic connections?

Generally speaking, the specific graphite mould is better to be used in unions that have the same measurements and technical characteristics. On the other hand, it is advisable to use a multiple mould when you are going to do connections with different measurements or different conductors. If you want more information, we recommend to follow the link wich explains several key factors should be considered when exothermic welding is employed.

In the following video we explain how to make an exothermic weld with a specific graphite mould:

In the following video we explain how to make an exothermic weld with a multiple graphite mould:

You can also use the moulds finder to know what materials are needed for each weld when specific moulds are used.

Advantages of using the Apliweld Secure+ exothermic welding technique

The exothermic welding presents many advantages compared with the mechanical unions. Moreover, Apliweld, due to its tablet format and the electronic ignition controller, adds up many additional advantages, most of them related to the occupational risk prevention and security.

Benefits of working with tablets instead of powder

- Apliweld ignition caps are not flammable. This is a clear handling advantage but also when storing it. It completely eliminates the occupational hazards.

- The charges of the tablets do not deteriorate with time, they are not affected by humidity.

- The powder format requires more than 10 different references to cover all of the different welding techniques. In the tablet format it is all reduced to one, two maximum.

- We always have the reference that you need, for the most common unions there is only one type of weld. The only thing that varies is the number of tablets needed to make the weld itself.

- The wind doesn´t affect the charge manipulation. Due to the compact tablet format, they don’t blow out.

The Apliweld Secure+ system reduces the risk of labour accidents

- The electronic initiator, with remote ignition system, prevents the operator from being exposed to any flammable risks.

- Prevents the risk of burns by projection of materials.

- Avoids the risk that transport, manipulation and storage of flammable products involve.

Perfect result in the exothermic welding

- Connections that last, does not deteriorate with time or with current peaks.

- It produces a permanent molecular fusion that does not corrode.

- The exothermic welding compared to a mechanical union, can stand electrical faults.

Apliweld exothermic welding according to standards and regulations

The exothermic welding method Apliweld®Secure+ has been certified and tested according to the following established standards:

- Tested by LOM demonstrating a null flammability of the tablet system and electronic ignition.

- Certified UL467 for every tested exothermic welding connection.

- Apliweld Secure+ completely meets with standards of the National security and hygiene institute of Spain.

For further information, consult with our team of experts.