A lightning rod with Early Streamer Emission device, also known by the abbreviation ESE or by the name of ionising lightning conductor, is a high-tech external lightning protection system. These ESE lightning conductors are also known as active lightning conductors and must comply with the applicable national and international standards or regulations (mainly UNE 21.186, NFC 17.102, Technical Building Code section SU8, and NP4426).

How does an ESE air terminal work?

The Aplicaciones Tecnológicas´ ESE lightning arresters are characterised by the fact that they contain an electro-pulsed generator that emits electrical impulses. Under normal conditions, the generator is in standby mode, but when storm conditions start, it is activated and remains in a pre-control state until the downward tracer is within range of the device. When this occurs, the upward tracer is formed, forming the path for the electrical discharge caused by the lightning.

The lightning current passes down the outside of the external armature and through the gap to conduct to ground, without damaging the internal circuitry. ESEs are classified by their advance time. The further the upward tracer is advanced (depending on the model chosen), it captures the downward lightning tracer at a higher point and prevents lightning strikes over a larger area.

Where can an ESE lightning rod be installed?

An ESE air terminal can be installed on any type of structure, providing a preferential and controlled point of lightning impact. The most recommended spaces for installation include both enclosed and open areas. This type of lightning rod is very versatile in terms of its installation; therefore, it can guarantee protection against lightning for all buildings and open spaces, controlling its discharge and conducting its energy safely to earth.

Aplicaciones Tecnológicas’ ESE lightning rods have been installed all over the world and in all kinds of places: sports areas, refineries, mine sites, emblematic buildings, etc.

It is always advisable to carry out a preliminary study to select the preferential location of the lightning conductor and the complementary materials necessary to achieve the greatest area of coverage, depending on the chosen site, its size and the environmental conditions in which it is located.

Basic elements for the installation of a lightning rod

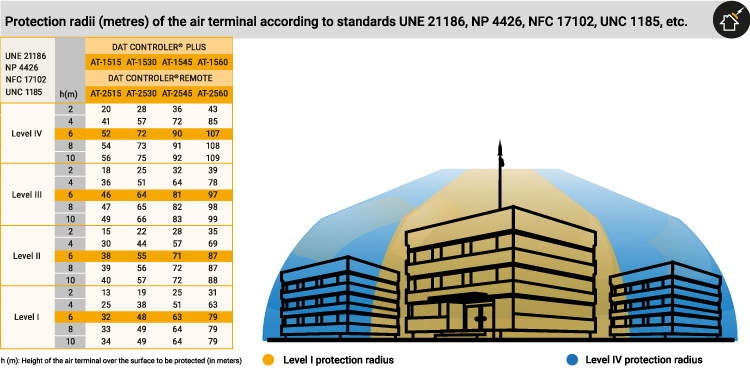

The main rule that should be considered for the installation of an ESE air terminal is the height at which the mast is to be placed. The mast should be installed so that the lightning rod is at least 2 metres above any other element within its protection radius. If it is installed on the roof of a building, given the definition of the protection radius in the regulations, the mast should ideally be at least 5 metres above the roof to guarantee the protection of the roof and all the objects on it. In addition, clamps and supports must be used to bear the weight of the lightning rod and mast, ensuring they are suitable for the conditions of the installation.

The ESE lightning rod, like all lightning protection systems, must be accompanied by an installation of down conductors and an earthing system. The path of the down conductor must be as straight as possible, following the shortest possible route and avoiding any sudden bending or upward trajectories. The down conductor should be installed on the outside of the building (whenever possible), avoiding the proximity of electrical or gas conduits or making equipotential bonding if the distance is not sufficient to avoid dangerous sparks.

For comprehensive protection against lightning, it would also be advisable to install a lightning event counter on the down conductor of the lightning rod, as the lightning protection regulations recommend carrying out an inspection of the protection system when it has received a discharge. For this purpose, Aplicaciones Tecnológicas has designed the ATLOGGER lightning counter, a device that monitors the electrical activity in the down conductor, recording the amplitude and polarity of the current impulse, as well as the date and time when the event took place. In addition, the ATLOGGER lightning counter makes an estimation of the load and the specific energy of the impulse.

With respect to earthing, it is essential to know that, although it is not a visible element, it is a fundamental and indispensable part of an electrical system and, therefore, in the protection against lightning.

The function of earthing in an electrical installation is to dissipate currents of any nature that may arise in the ground, such as fault currents at industrial frequency. In the case of the lightning protection system, it must dissipate the current of atmospheric discharges, protecting people and the electrical equipment of our home/business from dangerous potential differences. For more details please visit our article about the importance of proper earthing.

Steps to follow for the correct installation of an Early Streamer Emission (ESE) air terminal

Below are some simple steps that show how an ESE lightning rod installation should be carried out in general terms:

- Installation of the earthing system, earth resistance measurement and 1st phase of Conductiver Plus

- Installation of chemical anchor fixings.

- Assembly of the lightning conductor, adapter piece, mast and conductor.

- 2nd Conductiver Plus phase

- Positioning of the anchorage and fixing of the lightning conductor, fitting part and mast assembly

- Fixing the down conductor clamps.

- Installation of the lightning event counter and the guard tube to protect downcondutor.

- Installation of the earth pit and bonding bar.

- Final measurement of the earth resistance.

Through this link, you can watch a video on how the installation of a lightning rod is carried out by the team of professionals at Aplicaciones Tecnológicas.

When should the lightning rod be checked?

According to national and international regulations, lightning conductors must undergo periodic inspection and maintenance. The installation of a lightning conductor must be checked whenever the building structure is modified or repaired, or when the structure has been struck by lightning, and even if these situations do not occur, lightning conductor checks must be carried out on a regular basis.

As part of the maintenance protocol, the following types of checks are carried out:

Visual check: annual check in the case of protection level I and II installations. For protection levels III and IV, the visual check is to be carried out every two years at the latest.

The visual check should verify that:

- There is no damage due to lightning strike.

- The lightning conductor is intact in all its components.

- The continuity of the conductors is correct.

- The fixings are in good condition.

- There are no damaged parts due to corrosion.

- The state of the equipotential joints is correct.

Full check: for protection levels I and II, the full check shall be carried out at the latest every two years. For protection levels III and IV, verification shall be carried out at least every four years.

The full check comprises the visual inspections described above and other measures. It is required to verify the electrical continuity of the conductors and the correct functioning of the arrester according to the manufacturer’s instructions.

In the case of ESE type lightning conductors, the correct operation of the ESE air terminal must also be checked. Lightning conductors are installed at the highest point of the structure, always two metres above any element to be protected and generally on a six-metre mast, which means that in most cases it is difficult to access this head and puts the operator who has to carry out these checks at risk.

To facilitate this maintenance task, Aplicaciones Tecnológicas has incorporated a remote tester to the ESE lightning rod DAT CONTROLER REMOTE. In this way, it is not necessary to physically access the air terminal, as it has a system that checks the status daily and sends the result to a web application, where the updated data can be consulted at any time.

Full check of critical systems: this verification should be carried out at least once a year at all levels of protection.

In some countries, such as Mexico or India, among others, where the rainy season is very concentrated at one time of the year and is abundant, it is very important to perform lightning rod maintenance before the beginning of this period of the year. Contact a specialist to perform the necessary lightning rod maintenance and receive the appropriate advice.

At Aplicaciones Tecnológicas we also invite you to participate in our free online courses on lightning prevention and protection: ESE air terminals, surge protection devices, earthing systems, storm detectors… All our webinars are aimed at professionals in the sector and places are limited. Don’t miss the opportunity to learn in depth about the advantages of each product from the experts

If you would like to participate in these training sessions, please search for the topic you are interested in in your language, the course organised for your country and check the timetable through this link.